Facilities

MANUFACTURING EXCELLENCE

At siyashree, manufacturing is a passion. This passion has driven us to set up manufacturing facilities with extreme operational efficiencies. Over the years, we have earned an enviable reputation for flawless project execution and

management.

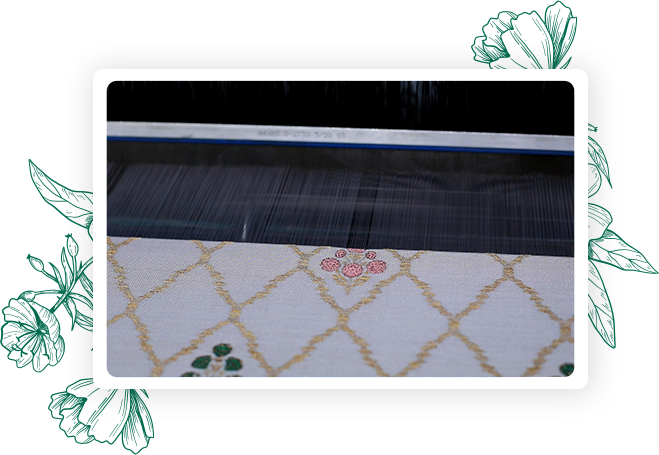

Weaving

Our weaving Unit is based in sachin & umargaon, Gujarat offers our clients maximum value addition. With state of art machinery with both an engineering and execution challenge have also improved our competitiveness and flexibility in order to complete the supply chain network to deliver the best quality fabrics with record lead times.

We have 20 fully automatic European (DONEAR) rapier looms equipped with world class staubli jacquard which produces best in class fabrics. Our production capacity is 3mm mts per annum.

Yarn

Group has been engaged in manufacturing of Dope Dyed

Polyester Filament Yarn, Fancy Yarn, Specialty Yarn, Airtex Yarn, Interlaced Yarn, Bi-shrinkage Yarn, Plied Yarn, High Bulk and Twisted Dyed Yarn at Surat unit for more than 2 decades.

Processing & Finishing

Design & Developement

Our development team brings variety of effect and feel in our fabric by using special type of Yarns been made in-house playing with the different properties of Yarns (like Luster, Shrinkage, Elongation etc.) with the library consist of approx 2000 shades in different Yarns.

Fabric Inspection

At Siyashree Textiles Fabric Inspection is the systematic observation of fabrics to decide whether it meets: Client’s specification in terms of count/construction, color, design, measurement specifications, hand/feel and other specific quality parameters laid down by the clients.

- The main objective of the inspection is the detection of defects and non-conformance as early as possible in the manufacturing process.

- Fabrics supplied to customers meet their specifications and standards; thereby they face less customer returns and recalls.

- Cutting inspected and approved fabric ensures not only finished garment quality but also reduces rejects, improves efficiency and timely deliveries.

- We uses the 4-Point System, also called the American Apparel Manufacturers (AAMA) point-grading system for determining fabric quality, is widely used by producers of apparel fabrics.

Safety & Environment

There is an unwavering commitment to safety and the Environment in all our operations. Siyashree adopts latest and best technologies for all new projects, invests in cutting edge technology for safe and reliable operations. The safety culture is reinforced with continuous training, updation of best industry practices and engaging some of the best experts to improve our primary effluent treatment process and safety systems. Continued focus on asset renewal ensures that all our assets are state of art and keeping with new technologies for improving safety.